Our Services

Online Estimator

It is important that we understand the scope of your Silo concerns so that we can prepare a proper estimate for you.

Aerated Flow Silos, aka Fluidized Flow Silos are used for fine powders.

Aerated Flow Silos, aka Fluidized Flow Silos are used for fine powders.

The material is aerated by pumping air into the bottom of the silo, making it behave as a fluid during the materials discharge from out of the bottom of the silo.

Discharge angles are between 5-10 degrees.

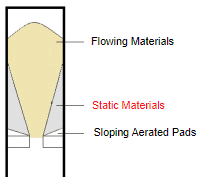

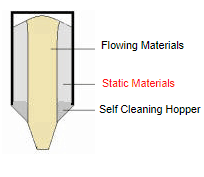

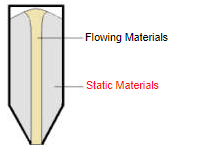

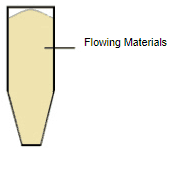

Please select from one of the following non-flowing silo material diagrams that best explains your need:

Black shaded areas represent non-flowing materials and blockage.

Lost Capacity Index: 4 | Lost Capacity Index: 2 | Lost Capacity Index: 3 | Lost Capacity Index: 5 |

Expanded Flow Silos are very similar to Mass Flow Silos.

They are ideally suited for short term storage of materials.

Their construction consists of a 45-60 degree angle tapering into a 68-72 degree cone angle.

.

Please select from one of the following non-flowing silo material diagrams that best explains your need:

Black shaded areas represent non-flowing materials and blockage.

Lost Capacity Index: 4 | Lost Capacity Index: 2 | Lost Capacity Index: 3 | Lost Capacity Index: 5 |

The Funnel Flow Silo is designed so the first materials used to fill the silo are the first materials emptied.

Please select from one of the following non-flowing silo material diagrams that best explains your need:

Black shaded areas represent non-flowing materials and blockage.

Lost Capacity Index: 4 | Lost Capacity Index: 2 | Lost Capacity Index: 3 | Lost Capacity Index: 5 |

The mass flow silo allows for materials to flow down the silo as a single column with no channels.

This eliminates aged, non-moving materials and the effects of segregation of materials stored within the silo.

The cone angle will be between 68-72 degrees depending on the material being stored.

Please select from one of the following non-flowing silo material diagrams that best explains your need:

Black shaded areas represent non-flowing materials and blockage.

Lost Capacity Index: 4 | Lost Capacity Index: 2 | Lost Capacity Index: 3 | Lost Capacity Index: 5 |